How to Choose a Rock Crusher

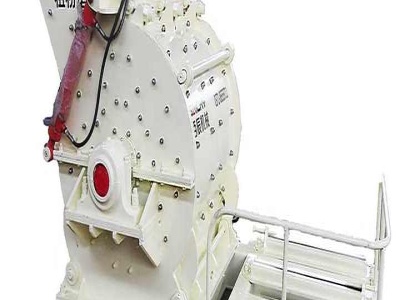

Impact vs Compression Style Rock Crushers. Compression crushers include jaw crushers, cone crushers, gyratory crushers and roll crushers. Impact crushers include vertical shaft impactors or horizontal shaft impactors. Compression crushers require much less maintenance; high impact crushers undergo more wear and tear due to the material colliding within the crusher.